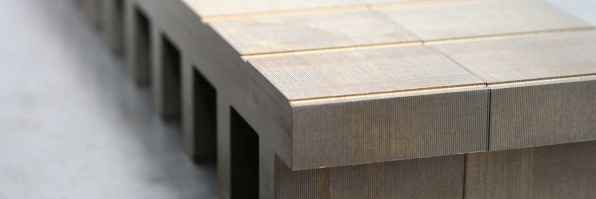

Baking of loose sheets

bonding varnish

In sample and small batch production

Alongside laser welding, the baking of loose sheets into packages using bonding varnish technology is a core competency at ERICH GRAU GMBH.

We have been reliably using this bonding varnish technology in sample and small batch production for many years. Here, loose sheets in a stamped or laser-cut form are stuck together by pressing under pressure and heat to form sheet packages. In this process, the bonding varnish insulation softens, sticks the sheets together and then hardens again.

The optimal sticking temperature and pressure are determined by the package geometry and the heating speed of the sheet package.

The necessary baking equipment is designed according to the sheet package geometry in our factory and is created in the in-house tool-making department.

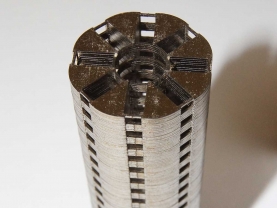

To manufacture the individual

sheets, we use modern laser cutting systems and are thus in a position to

create even complex shapes exactly to your designs.

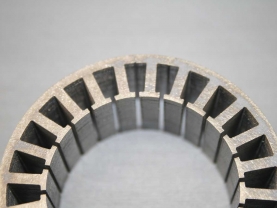

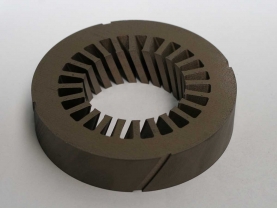

Significant advantages of bonding varnish are:

- High insulation between the individual sheets

- Reduction of wattage loss

- No frequency buzzing

- Optimal thermal conductivity

- Magnetic symmetry

- Prevention of corrosion thanks to the air and watertight enamel on the individual sheets

- Better mechanical resistance and stiffness of the package

Erich Grau GmbH

Stanzwerk für Elektrobleche

Uhlandstr. 3-7

D-74372 Sersheim

Tel.: 0 70 42 / 83 63 - 0

Industries

Automotive

Drive technology

Stator and rotor technology

Medical technology

Founded in 1952, ERICH GRAU GMBH is today a renowned, internationally active company in the field of stamping technology.

All of our customers' requirements are handled

with great care and attention. This applies for simple items as well as for

technically challenging parts.