FROM SAMPLE TO STANDARD PART

Sample production and prototype building

The more concrete the better, since your ideas can only be tested under real conditions when they take shape. In order to do this well, inexpensively and quickly, our sample production department is available. Depending of the quantities and requirements, a variety of processes are used for sample production:

For individual sheets:

- wire eroding sheets

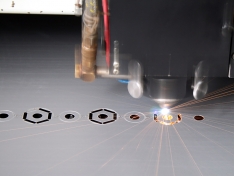

- laser cutting sheets

- stamping sheets with auxiliary tools

For packaging:

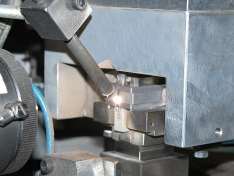

- laser welding

- gluing

- baking using baked enamel

Special production facilities for prototype building

Laser cutting facilities:

CO2 slab laser and fibre laser with max. cutting area of 1,250 x 2,500 mm

- High cutting speed and processing precision for thin sheet cutting with tolerances of ±0.03 mm

- Sheet thicknesses: 0.1 mm - 2.0 mm

Laser welding facilities:

ND:YAG solid state and diode lasers with outputs of up to 1 KW for high precision welding work

- For packages with thin cross-sections

- For packages made from different materials

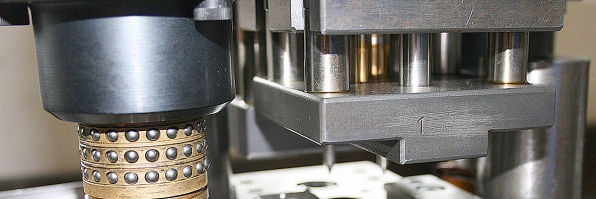

Auxiliary tools:

We can also manufacture auxiliary stamping tools for samples and prototypes. The properties of the parts manufactured with these match the later standard parts.

Equipment:

We manufacture part-specific packaging and holding devices for packages in welded, riveted or baked forms.

Erich Grau GmbH

Stanzwerk für Elektrobleche

Uhlandstr. 3-7

D-74372 Sersheim

Tel.: 0 70 42 / 83 63 - 0

Industries

Automotive

Drive technology

Stator and rotor technology

Medical technology

Founded in 1952, ERICH GRAU GMBH is today a renowned, internationally active company in the field of stamping technology.

All of our customers' requirements are handled

with great care and attention. This applies for simple items as well as for

technically challenging parts.