COMPENSATION ANNEALING OF LAMINATION CORES

COMPENSATION ANNEALING

When stamping sheets from electrical sheet, mechanical tensions are introduced around the cut edge, causing structural changes. This leads to deterioration of the magnetic properties of the material around the cut edges. The effects on the magnetic properties here are dependent on the quality of the material. Fundamentally, the higher the quality of the original material, i.e. the lower the wattage loss, the more the magnetic properties are negatively affected. This particularly applied for grain-oriented electrical steel.

In order to bring the magnetic properties of the material back to the level of the original material around the cut edges, lamination cores, in particular those made from grain-oriented electrical steel and with thin cross-sections, are often subjected to expansion annealing. Through expansion annealing, the mechanical tension in the material are removed and the original microstructure is reinstated. For insulated sheets, the insulation must be resistant to annealing. Grain-oriented electrical steel is coated on both sides with an inorganic Carlite insulation coating. This insulation coating is resistant to annealing and is necessary for the material's manufacturing process. In finished transformers, this coating serves as insulation against eddy currents.

Procedure for the compensation annealing process:

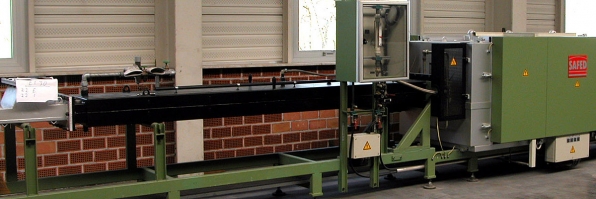

The annealing material is slowly heated to approx. 820 °C, kept at 820 °C for approx. 1 hour and then slowly cooled back to room temperature. In order to avoid oxidation of the sheet, the entire annealing process occurs in an inert atmosphere (N2).

Erich Grau GmbH

Stanzwerk für Elektrobleche

Uhlandstr. 3-7

D-74372 Sersheim

Tel.: 0 70 42 / 83 63 - 0

Fax: 0 70 42 / 83 63 - 63

Industries

Automotive

Drive technology

Stator and rotor technology

Medical technology

Founded in 1952, ERICH GRAU GMBH is today a renowned, internationally active company in the field of stamping technology.

All of our customers' requirements are handled

with great care and attention. This applies for simple items as well as for

technically challenging parts.